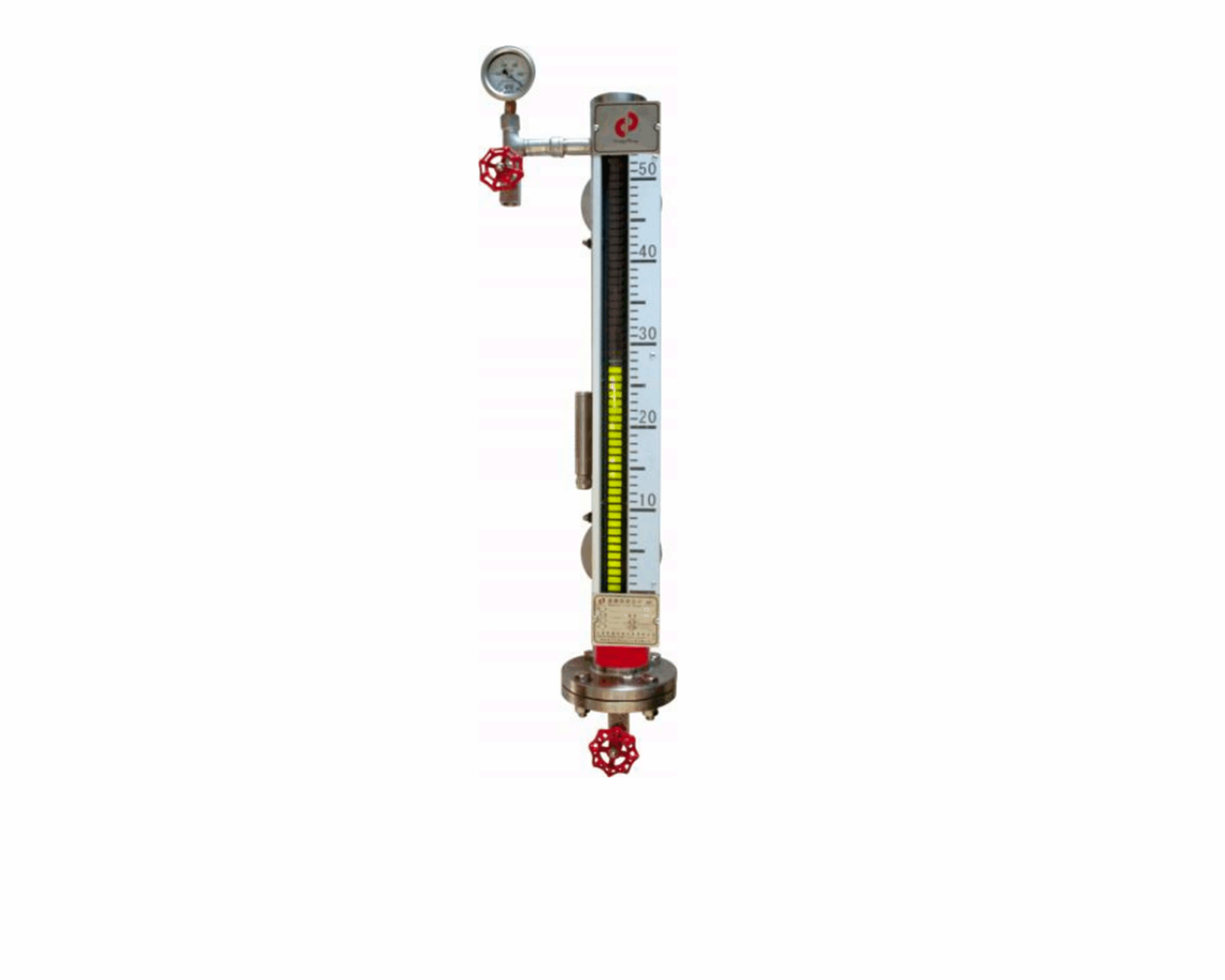

Magnetic flap level gauge is a common industrial liquid level measuring instrument. It intuitively displays the liquid level height by flipping the magnetic flap, and is suitable for a variety of working conditions. The following are its main functions and features:

1. Intuitive liquid level display

Two-color flap design: The red and white (or red and green) flap is turned by the magnetic float. Red usually indicates the liquid phase, and white/green indicates the gas phase. The liquid level changes can be clearly observed without power supply.

2. High pressure and corrosion resistance

Various materials: The main body can be made of stainless steel, PVC or fluorine-lined materials, suitable for corrosive media (such as acids and alkalis) or high-pressure environments (such as boiler drums).

3. Wide range of applications

Media type: It can measure liquids, slurries or high-temperature media (such as thermal oil). Some models are equipped with insulation jackets to prevent the medium from solidifying.

4. Auxiliary function expansion

Alarm output: A magnetic switch can be installed to realize high and low liquid level alarms (dry contact signals).

Remote transmission signal: Cooperate with the transmitter to output 4-20mA signals to support remote monitoring (such as DCS systems).

5. Low maintenance and reliability

No mechanical transmission: The flap is driven by magnetic coupling, no mechanical wear, simple maintenance and long life.

Typical application scenarios:

Local liquid level indication of chemical storage tanks and reactors

Boiler water level monitoring in the power industry

Sanitary liquid level measurement in the food and pharmaceutical industry

If you need to select a model, you need to consider the medium density, pressure level and installation method (side mounting/top mounting).